A muffle furnace or muffle oven (sometimes retort furnace in historical usage) is a furnace in which the subject material is isolated from the fuel and all of the products of combustion, including gases and flying ash. a muffle furnace is (usually) a front-loading box-type oven or kiln for high-temperature applications such as fusing glass, creating enamel coatings, ceramics and soldering and brazing articles. In ceramics muffle kilns were typically used for relatively low temperatures, for overglaze decoration.

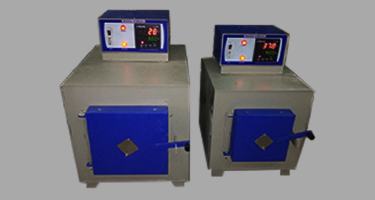

Very suitable for various purposes like gravimetric analysis for organic substance and measurement of quantity for coal and lime. With the distinguished Digital P.I.D controller, it provides you with precise control of temperature and easiness to operate this equipment. By the highly efficient heater installed in the four sides of the chamber, it directly heats materials which are handled. With this excellent feature, it surely reduces time of temperature climb. To prevent it from over heat and short circuit, the specialized safety device is installed.